Upgrading a Pinto with a V8 engine is an ambitious project that transforms a compact car into a powerful machine. This guide provides a step-by-step approach to successfully completing the swap, ensuring optimal performance and reliability. Proper planning and research are crucial to overcoming challenges and achieving desired results.

Overview of the V8 Pinto Engine Swap

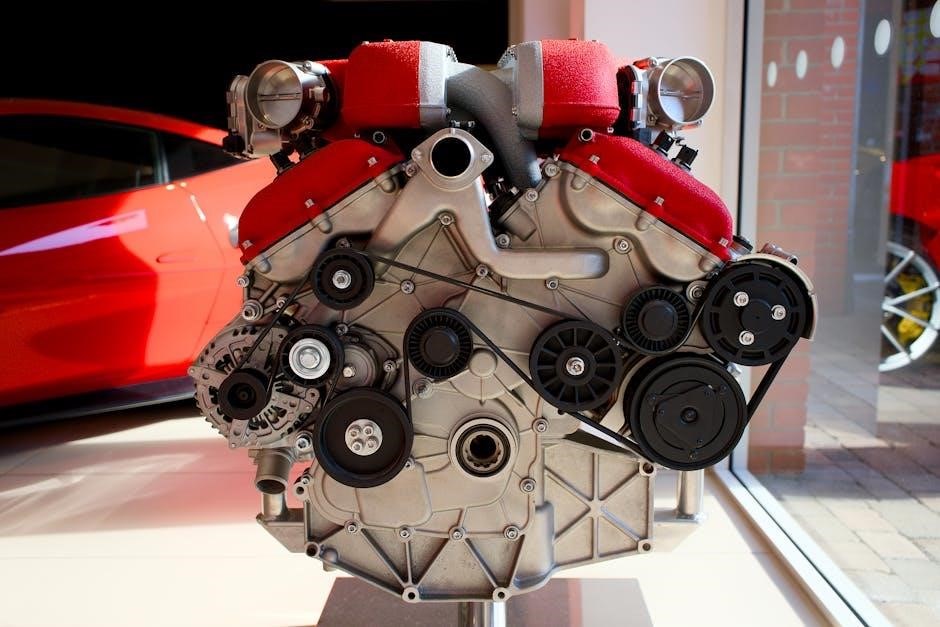

The V8 Pinto engine swap transforms the compact car into a powerhouse, offering significant power gains. Popular engine choices include the 302 and 351W, often sourced from Mustang IIs. This swap requires modifications to engine mounts, transmission, and cooling systems. The result is a more robust and thrilling driving experience. This guide provides steps to perform the swap successfully.

Importance of Proper Planning and Research

Proper planning and research are essential for a successful V8 Pinto engine swap. Identifying compatible components and understanding modifications ensures a smooth process. Researching parts, tools, and potential challenges saves time and money. A well-planned approach prevents costly mistakes and ensures the swap meets performance and reliability goals. Detailed preparation is key to overcoming technical and financial obstacles.

Cooling System Upgrades

The stock Pinto cooling system is inadequate for a V8 engine, necessitating upgrades to handle increased heat and power output. This ensures reliable operation and prevents overheating issues.

Why the Stock Pinto Cooling System is Inadequate

The stock Pinto cooling system is designed for a smaller, less powerful engine, making it insufficient for a V8. The radiator and fan are too small to manage the increased heat generated by the V8, leading to potential overheating issues. This inadequacy necessitates upgrades to ensure proper temperature regulation and prevent damage to the engine during operation.

Recommended Radiator and Fan Upgrades

A high-performance aluminum radiator is essential for the V8 swap, offering superior cooling capacity. Pair it with a high-CFM electric fan to ensure efficient heat dissipation. Additionally, consider upgrading the coolant hoses and water pump to handle increased demand. These upgrades are critical to maintaining optimal engine temperature and preventing overheating issues under heavy load or high-performance driving conditions.

Wiring Harness Modifications

A custom wiring harness is necessary to integrate the V8 engine with the Pinto’s electrical system, ensuring proper communication and power delivery for all components.

Necessity of a Custom Wiring Harness

A custom wiring harness is essential for integrating the V8 engine with the Pinto’s electrical system. The stock wiring is designed for the smaller engine and lacks the capacity to handle the V8’s higher power demands. A custom harness ensures proper communication between the engine and the vehicle’s electronics, including the ECU, ignition system, and fuel injection. This prevents electrical failures and ensures reliable performance.

Integrating the V8 with the Pinto’s Electrical System

Integrating the V8 with the Pinto’s electrical system requires careful adaptation. The stock wiring must be modified to support the V8’s higher power demands. This involves reworking the ECU, ignition system, and fuel injection components. Proper wiring ensures seamless communication between the engine and the vehicle’s electronics, preventing electrical failures and optimizing performance. Detailed planning and expertise are essential for a successful integration.

Transmission Compatibility

Choosing the right transmission is crucial for V8 swaps. Select a compatible model, whether manual or automatic, to handle increased power and ensure smooth operation.

Matching the V8 with the Right Transmission

Pairing the V8 with a suitable transmission is essential. Manual options like the T-5 or T-56 offer durability and control, while automatics such as the AOD or 4R70W provide smooth power delivery. Consider the engine’s power output and the need for adapter kits to ensure compatibility. Upgrading the rear axle, such as using an 8-inch unit from a Mustang II, enhances stability and performance.

Considerations for Manual vs. Automatic Transmissions

Selecting between manual and automatic transmissions involves considering clutch setup, pedal installation, shifter placement, and transmission mounts for manuals. Automatics require proper torque converter alignment, transmission cooler upgrades, and a compatible flex plate. Manuals offer better performance control, while automatics provide ease. Consider driving habits, parts availability, and maintenance costs when deciding.

Engine Mounts and Frame Modifications

Custom motor mounts and frame modifications are essential to securely install the V8 engine. Use factory mounts or fabricate custom ones to ensure proper alignment and stability.

Fabricating Custom Motor Mounts

Fabricating Custom Motor Mounts

Fabricating custom motor mounts ensures proper engine alignment and stability. Use steel for durability and consult chassis engineers for design accuracy. Ensure mounts are vibration-resistant and compatible with the V8’s weight. Proper alignment prevents frame stress and improves performance. Measure carefully and test fitments before final welding to avoid costly corrections later.

Using Factory Engine and Frame Mounts

Using factory engine and frame mounts from compatible models like the Mustang II simplifies the swap process. These mounts are designed to handle the V8’s weight and ensure proper alignment. Sourcing these mounts ensures compatibility and avoids fabrication challenges. Measure and fit carefully to maintain structural integrity and optimal performance.

Rear Axle Swap

The 8-inch rear axle from a Mustang II is ideal for the V8 Pinto swap due to its compatibility and strength. It fits well with minimal modifications, ensuring reliability and improved performance for the upgraded engine power.

Why the 8-Inch Rear End is Ideal

The 8-inch rear axle is perfect for the V8 Pinto swap due to its durability and compatibility with the Pinto chassis. Originating from the Mustang II, it offers a robust solution for handling increased power. Minimal modifications are needed for installation, making it a cost-effective choice. Its wider stance improves stability and weight distribution, enhancing overall drivetrain performance and reliability under the added stress of a V8 engine.

Sourcing the Rear Axle from a Mustang II

The 8-inch rear axle from a Mustang II is an excellent choice for the Pinto swap due to its compatibility and durability. It can be sourced from salvage yards or online marketplaces specializing in classic Ford parts. Ensure the axle is inspected for damage and properly refurbished before installation to guarantee reliability and performance with the V8 engine.

Fuel System Upgrades

Upgrading the fuel system is essential for the V8 engine to ensure adequate fuel delivery. This involves installing a high-pressure fuel pump and modern fuel lines to support the increased power demands of the engine.

Ensuring Adequate Fuel Delivery for the V8

A high-pressure fuel pump is necessary to meet the V8’s increased fuel demands. Upgraded fuel lines and injectors are required to handle the higher flow rate. Ensure all components are compatible with the engine’s specifications. Proper installation and routing of fuel system components are critical for reliability and performance. Always check for leaks and ensure system integrity before starting the engine.

Upgrading Fuel Lines and Pump

Installing a high-pressure fuel pump ensures consistent fuel flow to the V8 engine. High-flow fuel injectors are essential for meeting increased demand. Replace stock fuel lines with stainless steel or high-pressure hoses to prevent damage. Ensure all connections are secure and compatible with the V8 system. Proper installation prevents fuel starvation and enhances engine performance and reliability.

Exhaust System Modifications

A custom exhaust system is necessary for proper fitment and performance with the V8 engine. Ensure the exhaust is routed correctly to avoid interference with chassis components. Proper installation prevents damage and enhances engine efficiency.

Designing a Custom Exhaust System

Designing a custom exhaust system for a V8 Pinto swap involves selecting the right materials and routing. Stainless steel is recommended for durability. Ensure proper fitment to avoid chassis interference. Choose high-flow components like mufflers and catalytic converters for optimal performance. Welding expertise is essential for a leak-free system. Consider aftermarket kits or professional fabrication for reliability and efficiency.

Ensuring Proper Fitment and Performance

Proper fitment and performance are critical for a successful V8 Pinto swap. Test-fit all components to ensure clearance and alignment. High-performance headers and exhaust systems improve power output. Dyno testing is recommended to optimize engine calibration. Use high-quality gaskets and seals to prevent leaks. Ensure the exhaust system is well-insulated to maintain heat control and minimize noise. Regular inspections are essential for long-term reliability and performance.

Cost Considerations and Budgeting

Budgeting for a V8 Pinto swap requires careful planning. Costs include engine, transmission, and suspension upgrades. Sourcing affordable parts from salvage yards or online marketplaces can help reduce expenses. A detailed breakdown of estimated costs ensures financial preparedness for the project.

Estimating the Total Cost of the Swap

Estimating the total cost of a V8 Pinto swap involves considering engine, transmission, cooling, wiring, mounts, rear axle, fuel system, and exhaust upgrades. Prices vary widely based on part quality and sourcing. A basic swap might start around $3,000, while a high-performance build could exceed $10,000. Budgeting extra for unexpected expenses and labor is essential for a successful project.

Where to Source Affordable Parts

Affordable parts for a V8 Pinto swap can be sourced from online marketplaces like eBay and Craigslist, local salvage yards, or Ford enthusiast forums. Mustang II components, such as the 8-inch rear axle, are often compatible and readily available. Swap meets and Facebook Marketplace are also great resources for finding budget-friendly parts to keep costs manageable during the swap.

Troubleshooting Common Issues

Troubleshooting common issues during a V8 Pinto swap involves addressing cooling problems, electrical system incompatibilities, and transmission challenges. Always refer to the manual for diagnostic guidance and solutions.

Overcoming Cooling and Electrical Problems

Cooling issues arise as the V8 generates more heat than the Pinto’s stock system can handle. Upgrading to a larger radiator and high-performance fans ensures proper temperature regulation. Electrical challenges often stem from compatibility issues between the V8 and the Pinto’s wiring. Installing a custom wiring harness and integrating relays can resolve these problems, ensuring reliable power delivery to all components.

Additionally, a high-capacity alternator is recommended to prevent voltage drops and maintain stable electrical performance. Regular inspections and proper grounding are crucial to avoid electrical malfunctions. These modifications ensure the V8 runs smoothly within the Pinto’s framework, addressing both cooling and electrical demands effectively.

Addressing Transmission and Mounting Challenges

Selecting the right transmission is critical, as the V8’s power requires a compatible gearbox. A C4 or T5 transmission often works well, ensuring proper power delivery. Custom motor mounts are typically necessary to secure the V8, as factory mounts may not align correctly. Fabricating mounts or sourcing them from a Mustang II can provide a stable and reliable solution.

Proper alignment between the transmission and rear axle is essential for smooth operation and to prevent drivetrain stress. Additionally, reinforcing the frame may be needed to handle the added weight and torque of the V8 engine, ensuring long-term durability and performance.

A successful V8 Pinto swap requires meticulous planning, creativity, and perseverance. The end result is a powerful, unique vehicle that showcases your dedication and craftsmanship. Stay motivated, seek community support, and enjoy the thrill of driving your transformed Pinto. Happy swapping!

Key Takeaways for a Successful Swap

Thorough planning and research are essential for a smooth V8 Pinto swap. Upgrade cooling and wiring systems to handle the V8’s demands. Custom fabrications, like motor mounts, may be necessary. Seek expert advice and community support for troubleshooting. Patience and attention to detail will ensure a reliable and high-performance final result. Stay organized and enjoy the rewarding process of transforming your Pinto.

Encouragement and Final Recommendations

Embarking on a V8 Pinto swap is a challenging yet rewarding endeavor. Stay organized, seek guidance from experienced enthusiasts, and embrace the problem-solving process. Utilize resources like Randy Young’s manual and online forums for valuable insights. With persistence and dedication, your Pinto will become a powerful, unique vehicle that showcases your creativity and mechanical skills. Good luck and enjoy the journey!