A torque converter is a fluid-based coupling device that transfers rotational power between an engine and transmission․ Unlike manual transmissions, which use a clutch, torque converters provide smooth, automatic engagement and disengagement, enabling seamless power delivery without manual intervention․ They are commonly used in automatic transmissions but can also be integrated into manual systems for enhanced torque multiplication and smoother acceleration, particularly in high-performance or specialized applications․

1․1 Definition and Purpose

A torque converter is a fluid-based coupling device that transfers rotational power between an engine and transmission․ Its primary purpose is to multiply torque during acceleration and provide smooth, seamless power transfer․ Unlike manual transmissions that rely on a clutch, torque converters enable automatic engagement and disengagement, eliminating the need for manual gear shifts․ This makes them ideal for applications requiring smooth acceleration and reduced driver input, particularly in vehicles where ease of operation and performance are prioritized․

1․2 Evolution of Torque Converters

Torque converters have evolved significantly since their introduction in the 1930s, initially developed to enhance automatic transmissions․ Early designs focused on basic fluid coupling, but advancements introduced lock-up clutches for improved efficiency․ Modern torque converters integrate sophisticated materials and electronic controls, optimizing performance and fuel efficiency; Their application has expanded beyond traditional automatics, with adaptations for manual transmissions in high-performance and specialized vehicles, offering smoother acceleration and torque multiplication without sacrificing driver control․

1․3 Basic Operating Principle

A torque converter operates by using fluid dynamics to transfer rotational power from the engine to the transmission․ It consists of an impeller (driven by the engine), a turbine (connected to the transmission), and a stator to optimize fluid flow․ As the impeller spins, it propels fluid against the turbine, causing it to rotate․ This process allows for torque multiplication at low speeds and smooth engagement, eliminating the need for a manual clutch while maintaining engine idle in gear for manual transmissions․

Understanding Manual Transmissions

Manual transmissions require driver engagement through a clutch and gearshift to change gears, offering precise control and improved fuel efficiency․ They rely on mechanical connections rather than fluid-based systems like torque converters, providing a direct driving experience with enhanced driver control and responsiveness․

2․1 Overview of Manual Transmission Systems

Manual transmission systems require drivers to manually change gears using a clutch pedal and gearshift․ These systems are mechanically driven, relying on driver input to engage or disengage gears․ Unlike automatic transmissions, which use torque converters for smooth power transfer, manual transmissions provide direct control over gear shifts, enhancing fuel efficiency and driver engagement․ They are simpler in design, with fewer components, and often preferred for their responsiveness and cost-effectiveness in various vehicle applications․

2․2 Role of the Clutch in Manual Transmissions

The clutch is a critical component in manual transmissions, enabling the driver to disconnect and reconnect the engine from the transmission․ It allows smooth gear shifts by temporarily isolating the engine’s power, preventing gear grinding․ Pressing the clutch pedal disengages the engine, while releasing it re-engages power to the transmission․ This mechanism provides precise control over gear changes, enhancing driver flexibility and vehicle responsiveness, especially in varying driving conditions;

2․3 Advantages of Manual Transmissions

Manual transmissions offer several advantages, including better fuel efficiency, lower cost, and increased driver control․ They are generally lighter and simpler in design compared to automatics, reducing power loss and improving acceleration․ Drivers can exploit engine braking and gear ratios more effectively, enhancing performance in both city and high-performance driving scenarios․ Additionally, manual transmissions often require less maintenance and are more durable, making them a preferred choice for enthusiasts and those seeking a more engaging driving experience․

Torque converters can be integrated into manual transmissions to enhance torque multiplication and smooth acceleration, offering improved performance in specialized applications, though they introduce complexity and require careful setup․

3․1 How Torque Converters Integrate with Manual Transmissions

Torque converters can be integrated into manual transmissions by replacing the traditional clutch system with a fluid-based coupling․ This allows for automatic engagement and disengagement of power between the engine and transmission, enabling smooth acceleration without manual clutch operation․ In this setup, the torque converter provides torque multiplication at low speeds, similar to automatic transmissions, while still allowing manual gear shifts․ This hybrid approach combines the benefits of both systems, offering improved performance in high-torque applications while maintaining driver control over gear selection․

3․2 Benefits of Using a Torque Converter in Manual Transmissions

Using a torque converter in a manual transmission offers several advantages, including smoother power delivery and reduced wear on mechanical components․ It eliminates the need for constant clutch engagement, providing a more comfortable driving experience; Additionally, torque converters enable torque multiplication at low speeds, enhancing acceleration and performance in demanding conditions․ This integration also reduces driveline shock, making it ideal for heavy-duty or high-torque applications where traditional manual transmissions may struggle to maintain smooth power transfer․

3․3 Challenges and Limitations

Using a torque converter in a manual transmission presents challenges, such as reduced driver control and increased mechanical complexity․ The system may require additional components like pumps and coolers, adding weight and cost․ Moreover, torque converters can introduce inefficiencies at higher speeds, potentially reducing fuel economy․ They also limit the ability to manually modulate power delivery, which can be a drawback for drivers accustomed to precise control․ These trade-offs must be carefully considered when integrating a torque converter into a manual transmission system․

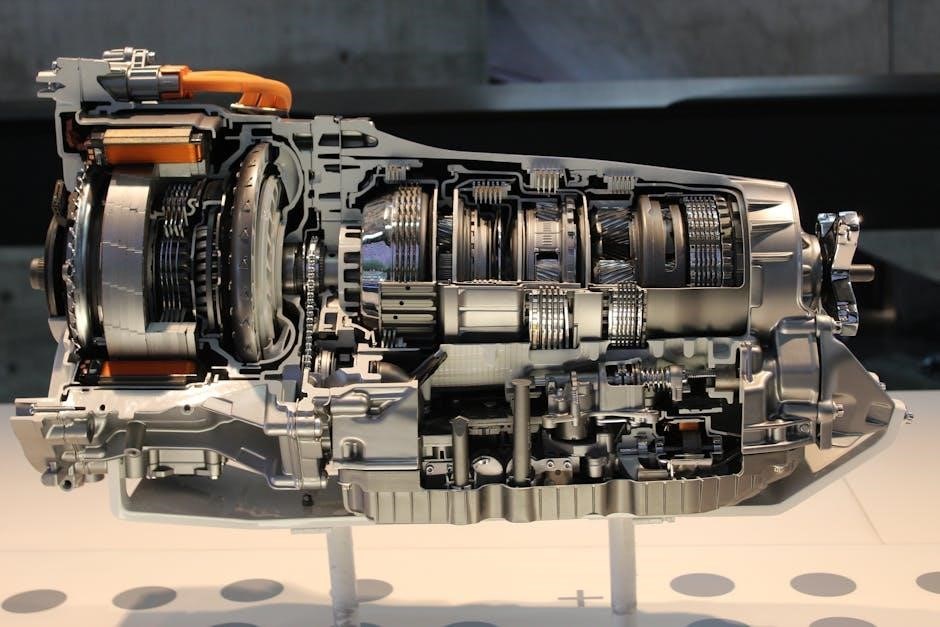

Components of a Torque Converter

A torque converter consists of an impeller, turbine, and stator․ The impeller, driven by the engine, pumps fluid to the turbine, which powers the transmission․ The stator optimizes fluid flow, enhancing torque multiplication․ This setup enables smooth power transfer in manual transmissions․

4․1 Impeller, Turbine, and Stator

The impeller, turbine, and stator are the primary components of a torque converter․ The impeller, connected to the engine, circulates transmission fluid to the turbine, which drives the transmission․ The stator, positioned between the impeller and turbine, redirects fluid flow, amplifying torque during acceleration․ This hydraulic system ensures smooth power delivery in both automatic and manual transmissions, enabling efficient torque multiplication and seamless gear engagement․

4․2 Torque Converter Clutch (TCC)

The Torque Converter Clutch (TCC) is a mechanical component that engages and disengages the torque converter, allowing direct engine-to-transmission connection․ In manual transmissions, the TCC enhances control by locking the converter during specific conditions, improving fuel efficiency and reducing wear; It typically engages at higher speeds or under light load to minimize slippage, providing a more responsive driving experience․ The TCC is crucial for balancing the benefits of torque multiplication with the precision of manual gear control, optimizing both performance and efficiency․

4․3 Fluid Dynamics and Pressure Control

Fluid dynamics in a torque converter rely on the movement of transmission fluid to transfer torque between the impeller and turbine․ Pressure control systems regulate fluid flow, ensuring optimal performance․ In manual transmissions, precise pressure management is crucial to prevent slippage and maintain smooth power delivery․ Sensors and solenoids work together to monitor and adjust pressure, enabling efficient torque multiplication and minimizing wear on components․ Proper fluid pressure ensures the converter operates seamlessly, enhancing both performance and longevity in manual transmission applications․

Engineering and Design Considerations

Torque converters for manual transmissions require precise engineering, focusing on material selection, thermal management, and stall speed calculation․ Advanced designs optimize fluid dynamics and pressure control for efficiency and durability, ensuring smooth power delivery across various driving conditions․

5;1 Sizing and Stall Speed Calculation

Sizing and stall speed calculation are critical for optimizing torque converter performance in manual transmissions․ Proper sizing ensures the converter matches the engine’s torque output and operating RPM range․ Stall speed, the maximum RPM before the turbine engages, must be calculated to avoid excessive slippage and heat generation․ Accurate calculations prevent overheating and ensure efficient torque multiplication, especially during acceleration․ Engineers use dynamometer testing and simulation tools to determine ideal stall speeds and size converters for specific applications, ensuring optimal performance and longevity․

5․2 Material Selection and Durability

Material selection is vital for torque converter durability in manual transmissions․ High-strength steels and advanced composites are often used to withstand intense torque and heat․ The stator and impeller are typically made from durable materials to handle repeated stress․ Surface treatments, like heat-treating, enhance longevity․ Proper material choices ensure the converter can endure high-performance demands without premature wear․ Durable construction is critical for maintaining consistent power delivery and preventing mechanical failure, especially in high-stress applications such as racing or heavy-duty use․

5․3 Thermal Management and Cooling Systems

Effective thermal management is crucial for torque converters in manual transmissions, as excessive heat can degrade performance and lifespan․ Cooling systems, such as transmission fluid circulation and external heat exchangers, are essential to dissipate heat generated by friction and fluid dynamics․ Proper coolant flow and ventilation ensure optimal operating temperatures, preventing damage to internal components․ Advanced materials and designs, including increased surface area for heat dissipation, further enhance thermal efficiency․ Maintaining consistent temperatures is vital for reliable power delivery and long-term durability in demanding applications․

Installation and Maintenance

Proper installation involves aligning the torque converter with the transmission and ensuring secure coupling․ Regular maintenance includes inspecting fluid levels, checking for leaks, and replacing worn components to ensure optimal performance and longevity․

6․1 Step-by-Step Installation Guide

Begin by draining the transmission fluid and disconnecting the battery․ Remove the transmission pan to access the torque converter․ Carefully pull the converter straight out, taking note of its alignment․ Install the new torque converter by aligning the splines and gently pushing it into place․ Reattach the transmission pan, refill the fluid, and reconnect the battery․ Perform a test drive to ensure smooth operation and check for any leaks or unusual noises․

6․2 Maintenance Tips for Longevity

Regularly check the transmission fluid level and condition, replacing it as recommended․ Avoid extreme heat by ensuring proper cooling systems function․ Refrain from aggressive driving to prevent unnecessary wear․ Inspect the torque converter for leaks or damage and address issues promptly․ Always follow proper installation procedures to avoid misalignment․ Schedule regular servicing to maintain optimal performance and longevity․ Perform test drives after maintenance to ensure smooth operation and address any concerns early․

6․3 Common Issues and Troubleshooting

Common issues with torque converters in manual transmissions include slipping, overheating, or vibrations․ Slipping may indicate low fluid levels or worn friction surfaces․ Overheating can occur due to excessive load or poor cooling․ Vibrations often result from misalignment or imbalance․ Troubleshooting involves checking fluid levels, inspecting for leaks, and ensuring proper installation․ Addressing these issues promptly can prevent further damage and ensure optimal performance․ Regular servicing and monitoring are essential to maintain reliability and longevity of the system․

Performance and Efficiency

Torque converters enhance performance by multiplying torque, enabling smoother acceleration․ However, they can add complexity and slightly reduce fuel efficiency compared to pure manual systems․

7․1 Acceleration and Power Delivery

Torque converters in manual transmissions enhance acceleration by multiplying torque at low speeds, enabling quicker launches and smoother power delivery․ This feature is particularly beneficial in high-performance applications, where rapid acceleration is critical․ By maintaining optimal engine RPM during gear shifts, torque converters minimize power loss, allowing for more responsive throttle input․ However, they can introduce slight delays in power transfer compared to direct clutch engagement, and their added complexity may reduce fuel efficiency in certain driving conditions․

7․2 Fuel Efficiency Comparison

Torque converters in manual transmissions can impact fuel efficiency, often resulting in slightly lower mileage compared to traditional manual systems․ While they provide torque multiplication and smoother power delivery, the constant fluid coupling can consume additional engine power, especially in low-load conditions․ However, in high-performance or heavy-duty applications, the efficiency trade-off may be justified by improved acceleration and torque output․ Overall, fuel efficiency depends on driving conditions and specific system design, making manual transmissions with torque converters a balanced choice for certain use cases․

7․3 Impact on Driver Experience

Integrating a torque converter into a manual transmission enhances driver comfort by eliminating the need for constant clutch engagement and gear shifting․ This results in smoother acceleration and reduced driver fatigue, especially in heavy traffic or hilly terrain․ However, it may slightly reduce the direct control and responsiveness typically associated with manual transmissions, offering a balanced compromise between convenience and driving dynamics․

Applications in Different Vehicles

Torque converters are used in high-performance vehicles, heavy-duty machinery, and specialized applications like racing, industrial equipment, and custom builds, enhancing power delivery and operational efficiency․

8․1 High-Performance Vehicles

In high-performance vehicles, torque converters are often paired with manual transmissions to optimize acceleration and power delivery․ This combination allows for rapid gear shifts while maintaining smooth torque multiplication, especially in racing applications where instant power transfer is critical․ The integration enhances drivetrain efficiency, enabling vehicles to achieve faster 0-60 times and better control during high-speed maneuvers․ This setup is particularly favored in specialized racing cars and custom builds where extreme performance is demanded․

8․2 Heavy-Duty and Industrial Applications

Torque converters are widely used in heavy-duty and industrial applications, such as construction equipment and industrial machinery, where consistent power delivery is essential․ They enable smooth operation under varying loads, reducing mechanical stress on the drivetrain․ In industrial settings, torque converters enhance efficiency and reliability, particularly in applications requiring high torque at low speeds․ This makes them ideal for heavy-duty vehicles and machinery, ensuring optimal performance in demanding environments while maintaining operational durability․

8․3 Specialized Use Cases

Torque converters are utilized in niche applications like racing and aviation tugs, where precise control and rapid acceleration are critical․ Racing cars benefit from torque converters for consistent power delivery and quicker launches․ Aircraft tugs rely on them for smooth, controlled movements․ Additionally, some custom manual transmission setups integrate torque converters for extreme applications, offering a unique blend of automatic-like smoothness and manual drivetrain control, catering to specific performance or operational requirements in specialized vehicles or machinery․

Comparison with Automatic Transmissions

Manual transmissions use a clutch, while automatics rely on a torque converter for smooth power transfer․ Automatics offer convenience but may lack the efficiency and driver control of manuals with torque converters, which can enhance acceleration and responsiveness in specialized setups․

9․1 Gear Shift Mechanism

In automatic transmissions, the torque converter facilitates seamless gear shifts without manual intervention, relying on fluid pressure and sensors to engage gears․ In contrast, manual transmissions require a clutch pedal and gearshift, offering direct driver control․ However, integrating a torque converter with a manual transmission creates a hybrid system, where the converter handles low-speed torque multiplication while the driver still operates the clutch for gear changes, blending automatic ease with manual precision․ This setup enhances low-end power delivery and smoothness․

9․2 Driver Control and Flexibility

Manual transmissions offer greater driver control and flexibility, as the clutch and gearshift enable precise gear engagement and disengagement․ In contrast, torque converters in automatic transmissions reduce driver involvement, relying on sensors and fluid pressure to manage shifts․ However, combining a torque converter with a manual transmission creates a unique balance, allowing drivers to maintain control while benefiting from torque multiplication at low speeds․ This hybrid approach appeals to enthusiasts seeking both performance and convenience, though it may limit the direct mechanical connection of a traditional manual setup․

9․3 Performance Metrics

Manual transmissions with torque converters balance performance and efficiency, offering faster acceleration and better fuel economy compared to traditional automatics․ They maintain direct driver control while providing smooth power delivery․ Automatics, however, prioritize convenience over driver involvement․ Performance metrics like 0-60 times and torque multiplication highlight the strengths of each system, with manuals excelling in responsiveness and automatics in seamless operation․ The choice depends on whether priority is given to driver engagement or hassle-free driving experience․

Future Trends and Innovations

Future trends include hybrid systems combining manual and automatic features, smart torque converters with adaptive controls, and integration with electric vehicles for enhanced efficiency and performance․

10․1 Hybrid Systems

Hybrid systems integrate torque converters with manual transmissions to optimize fuel efficiency and performance․ These systems combine the precision of manual control with the smooth torque multiplication of a converter․ By incorporating electric motors and advanced control algorithms, hybrids achieve seamless power delivery during gear shifts․ This blend reduces emissions and enhances acceleration, making it ideal for modern vehicles․ The synergy between manual and automatic features offers drivers the best of both worlds, addressing the demand for eco-friendly, high-performance solutions․

10․2 Smart Torque Converters

Smart torque converters leverage advanced technologies like sensors and AI to optimize performance in manual transmissions․ These converters adapt to driving conditions, adjusting torque multiplication and slip dynamically․ They enhance fuel efficiency and reduce wear by minimizing unnecessary engagement․ Integration with electronic control units ensures precise coordination with engine and transmission systems․ Smart torque converters represent a leap forward, offering real-time adjustments for better driver experience and vehicle efficiency, making them a key innovation in modern automotive engineering․

10․3 Integration with Electric Vehicles

Torque converters are being explored for integration into electric vehicles (EVs) to enhance power delivery and efficiency․ By optimizing torque multiplication, they can improve EV acceleration and range․ Smart torque converters, equipped with advanced sensors, adapt to electric motor characteristics, ensuring seamless power transfer․ This integration addresses the unique demands of EVs, such as instantaneous torque and silent operation, making torque converters a promising component in next-generation electric drivetrains, potentially revolutionizing both manual and automatic EV transmissions․

Case Studies and Examples

Case studies highlight torque converters in manual transmissions for racing, custom builds, and industrial machinery, such as the Unimog 406 and Garage54’s unique manual transmission projects․

11․1 Racing Applications

In racing, torque converters are sometimes paired with manual transmissions to optimize acceleration and power delivery․ This setup allows drivers to harness high torque multiplication during launches while maintaining manual control for precise gear shifts․ For instance, drag racing cars often use torque converters with manual transmissions to achieve quicker 0-60 times․ Additionally, some rally cars and high-performance vehicles adopt this hybrid approach to balance automatic torque engagement with manual driving dynamics, enhancing both speed and driver control․

11․2 Custom Builds and Modifications

Custom builds often experiment with torque converters in manual transmissions for unique performance benefits․ Enthusiasts may install a torque converter to achieve smoother low-speed operation and increased torque multiplication, particularly in high-torque engines․ This modification is challenging but offers distinct advantages for specific applications․ For instance, it can reduce clutch wear and provide automatic engagement at low speeds while retaining manual gear control․ Such setups are popular in extreme applications or custom projects where traditional systems fall short․

11․3 Industrial Machinery Implementations

Torque converters are increasingly used in industrial machinery for applications requiring smooth power transfer and torque multiplication․ Heavy-duty equipment, such as aircraft tugs and specialized vehicles, often employs torque converters to handle high-torque demands․ For instance, the Unimog 406 utilized torque converters in manual transmissions for enhanced performance in industrial settings․ This setup allows for efficient operation in challenging environments, combining the benefits of automatic engagement with manual control, making it ideal for heavy-duty and industrial use cases where traditional systems may not suffice․

Torque converters offer unique advantages when integrated with manual transmissions, enhancing torque multiplication and smoothing acceleration․ Their versatility in high-performance and specialized applications highlights their adaptability and efficiency․

12․1 Summary of Key Points

Torque converters integrate with manual transmissions to enhance torque multiplication, smoothing acceleration, and improving driver experience․ They enable automatic engagement and disengagement, reducing manual intervention while maintaining performance․ Ideal for high-performance and specialized applications, torque converters offer versatile solutions for modern and extreme driving conditions․ Their design and efficiency make them a valuable component in optimizing power delivery and vehicle responsiveness, catering to both everyday and industrial uses․

12․2 Final Thoughts on Torque Converters for Manual Transmissions

Torque converters offer a unique solution for manual transmissions by blending automatic engagement with manual control․ They provide smooth power delivery and torque multiplication, enhancing acceleration and driver experience․ While they excel in high-performance and specialized applications, they also adapt well to everyday driving․ Their ability to balance automation and driver input makes them a versatile component, offering improved efficiency and responsiveness․ This innovative integration highlights the potential for torque converters to redefine manual transmission systems in modern vehicles․